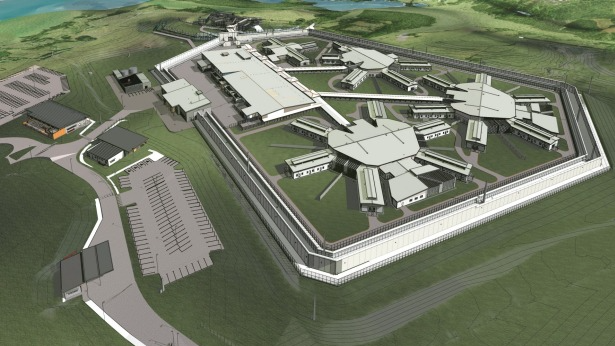

In 2015 with construction due to begin on the maximum-security wing at Paremoremo (Auckland Prison Estate), Fletcher Construction (FCC) who won the contract for the replacement of the 261 bed maximum security facility considered the use of high-strength, precast concrete panels for its construction, but had to reconsider their use when lead times and design inflexibility meant construction timeframes couldn’t be met.

“When using precast panels in construction the design needs to be finalised very early in the building sequence so that embedded services and other cast-in elements can be incorporated into the panels,” explains Stuart West, Project Manager for FCC. “The procurement timeframe of precast panels was a real issue for this project. We wanted to use blockwork construction which is far more flexible in that changes can be made to the design much later and there is no long lead time impact.”

However the Department of Corrections had concerns about using standard blockwork for prisoner accessible areas. In addition, the rough surface of the block made it very difficult to keep clean.

So FCC, and their consultant Beca Consultants, approached Firth to find out if a high strength block could be developed to satisfy the project’s time frames and allay the Departments concerns about security.

New MaxiBloc and MaxiMortar

With input and direction from Structural Engineer David Cooke from Beca Consultants, Steve and the Firth masonry team produced the first high strength, custom-made MaxiBloc. “Before we could test the block’s strength we also had to produce a high strength mortar - MaxiMortar - which our Dricon team helped produce,” says Steve Crossland, Technical & Specifications Manager (Masonry) Firth.

Put to the test

The suitability of the high strength blockwork for use in a maximum-security environment was established through a robust testing regime. Testing was undertaken on the proposed MaxiBloc, precast concrete panels and standard blockwork. “Fletcher Construction produced test walls of each of these materials which were manufactured, constructed and QA tested to the Design Engineers' specifications and appropriate NZ Standards,” says David.

Each of the walls were put to the test using a battering ram style attack (using a 36 kg steel cylinder with a sharpened end) to provide a simulated evaluation of the wall’s ability to resist violent attacks by sustained manpower using benches, doors or tables.

“Under the American Standard F2322 the walls were subjected to 600 blows within a hour with the resultant damage compared,” says David. “MaxiBloc faired very well with no penetration of the block wall itself and it compared as well as the test to the precast panels.”

MaxiBloc gets the green light

With a range of other requirements such as a high strength block fill, abrasion testing and a specialised coating to resist damage and allow the surfaces to be easily cleaned, the collaboration between Firth and FCC scored a win with the Department of Corrections giving MaxiBloc the green light for use at the Auckland maximum security prison.

A total of 150,000 standard blocks and 225,000 MaxiBlocs will be laid by completion of the project.

Steve explains that MaxiBloc weighs 15kgs as opposed to 12kgs for standard 20 series block so, to ensure the blocks are laid to the accepted standards and using approved techniques, an installation manual was drafted and blocklayers were required to attend training on laying methods. “We also added a minimum dosage of red oxide to both the mixes of MaxiBloc and MaxiMortar which has given each of the products a pink tinge,” adds Steve. “This is to ensure that contractors and everyone concerned can identify which are the high strength blocks and which aren’t.”

“We have about 11 - 12 months left on site with most of the bones of all of the buildings up and the roofs still to go on some,” says Stuart. “We are extremely happy with the result of our collaboration with our sister company Firth and support from David at Beca Consulting. Producing the MaxiBloc will make construction a lot easier and certainly a lot quicker - we estimate by about six months - which, now we have allayed their fears, the Department of Corrections is also very happy about.”

Project Details

Principal: Department of Corrections

Managed by: NextStep Partners

Consultant: Beca Consultants

Customer: Fletcher Construction

Location: Auckland Prison Estate (Paremoremo)

Product: Firth MaxiBloc and MaxiMortar