Canterbury Concrete's expertise on speed dial

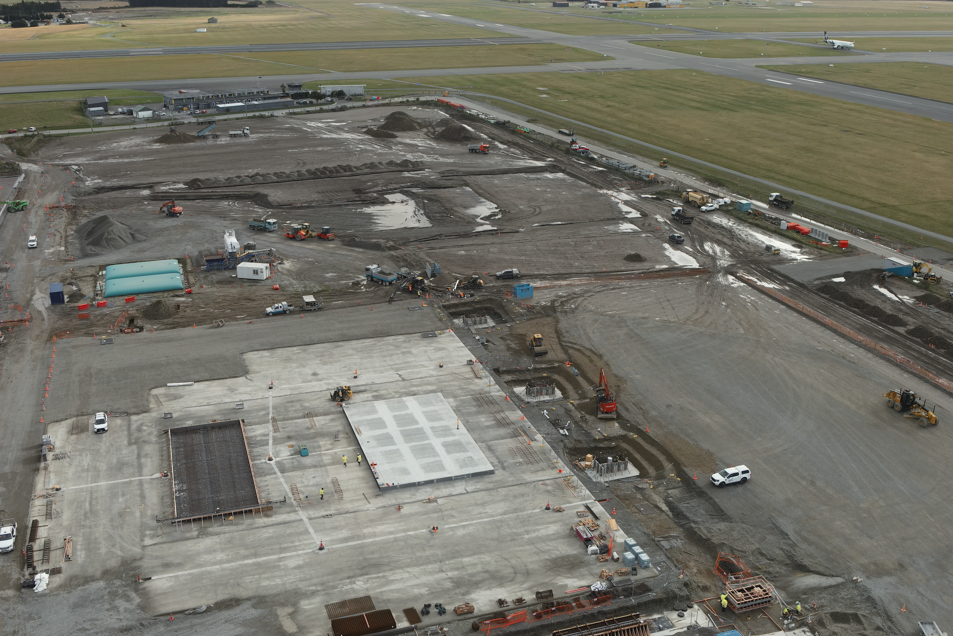

For over five years, Canterbury Concrete and Fulton Hogan have joined forces on a diverse array of projects at Christchurch Airport. “We first started collaborating with the Canterbury Concrete crew on concrete hardstands back around 2020 or 2021, so we’ve built a solid working relationship over the years and know their team inside out,” says James Cockburn, Project Manager at Fulton Hogan.

Freight Hub Apron

Most recently, Canterbury Concrete has been supplying Fulton Hogan with product for the Freight Hub Apron Extension - a development set to double the airport’s freight-handling capacity.

| The multi-million-dollar project will expand the freight parking area, known as an apron, to the size of six football fields, allowing space for up to eight 737-sized planes or four larger 757 aircraft. |

“The aprons are used by large, heavy aircraft so a highly technical mix was designed with low shrinkage to minimise the risk of cracking while also being fit for purpose for the heavy workload expected,” says Ian Kamo from Canterbury Concrete Sales. “We started most pours around 5am before everything got busy.”

“Initially, the work on the Freight Hub was expected to require about 8,000m³ of concrete, with 5,500m³ poured to date,” adds Ian. “There have been a few delays, but we expect to supply the remaining 2,500m³ between February and May 2026. It’s been quite high spec, but nothing we can’t handle.”

An early-use specialist mix

James says he has called on Canterbury Concrete for additional work around the airport - projects with tricky requirements and tight schedules.

“We were asked to produce a mix for a runway repair that started at midnight so the runway could be in service by early morning,” says Nan Jiang, Materials Manager (Southern) for Firth. “A very early strength was required for this mix which is quite tricky. The mix has a high cement content with a large dosage of set accelerators. The batching to discharge had to be completed in a very short timeframe, with no delays during delivery.”

Nan says a large number of early-strength tests were cast at Firth’s Research & Development lab where the concrete temperature was measured before the project even commenced to ensure that the runway could be used after just six hours!

“Our partnership with Canterbury Concrete is excellent,” James says. “They regularly support our projects, and we are pleased with the results.”

“Fulton Hogan often reaches out to us for support, and we’re always glad to assist,” says Ian.

|

Principal: Customer: Location: Product: |

Christchurch |