Concrete a deliberate choice for Wai Ariki – Rotorua’s world-class luxury spa facility

After more than five years of development, Wai Ariki Hot Springs and Spa, a luxury, cultural wellness destination built on the beautiful shores of Lake Rotorua, opened this year to local and international visitors. This majestic and beautiful facility was inspired, built and funded by local iwi - Ngāti Whakaue - with the aim of curating a uniquely Te ao Māori experience for guests. Designed to take into account the geothermal nature of the area, the use of concrete throughout the stunningly beautiful spa complex was a deliberate choice for Auckland Architects RCG due to its versatility, strength, and beauty … with Firth delighted to supply the technical expertise and specialist mixes required to ensure longevity of this cultural gem.

Background

“The client came to us about 10 years ago with a vision of building an Iwi-owned spa complex that would be run by Ngāti Whakaue iwi (Pukeroa Lakefront Holdings Limited)," says Alex Liang, Associate Director of RCG. “The brief was to create a luxury spa and wellness facility like no other – architecturally, experientially and culturally."

Alex says that the desire was that the build be funded and led by Māori, and that it benefits from being compiled through the lens of Te Ao Māori – the Māori world. “The complex is a unique development for Ngāti Whakaue,” as David Tapsell, Chairperson of Pukeroa Oruawhata Lakefront Holdings Limited explains. ”There has been a deep focus on authenticity throughout. Every element is founded on Ngāti Whakaue principles, practices and stories, reflecting the whakapapa (kinship) we have with the natural environment, from the heavens to the water and the earth.”

Concrete chosen for durability and longevity

“Due to the extremely corrosive nature of the land and geothermal water, all materials were selected to meet the building code requirements for durability,” explains Alex. “In addition, as our client is a generational developer, the building had to be able to go the distance.”

Alex talks about the materials chosen for Wai Ariki. “A significant amount of the walls are precast or masonry concrete. All the concrete in the subfloor had to be minimum insitu or precast. Then we chose Innowood (a sustainable timber alternative manufactured from wood waste) for the wall and ceiling claddings to create a warm membrane roof for the pool areas. There are probably enough tiles to make this one of the biggest tiling projects in Aotearoa! Aluminium and stainless steel have also been used throughout the facility as it is also highly resistant to corrosion.”

Firth’s expertise comes to the fore …

Tim Bulmer, Regional Materials Manager (Bay of Plenty) for Firth, talks about designing the right concrete mixes to be used at Wai Ariki. “The key thing for us here was the XA3 requirements. This is a special section of the Concrete Structures design standard which makes a note of geothermal areas which are at the extreme limit of aggressive environments.”

“It’s always 45MPa+ concrete with an 8% addition of silica fume (microsilica), which has a bit of a reputation for being sticky and hard to use, while being exceptionally durable,” adds Tim. “We managed to make two special mixes for the main contractor which could be pumped and had to get through some tight spaces full of reinforcing steel! The Firth team in Rotorua are no strangers to the less aggressive XA2 environment for surrounding areas, but due to the location of this project we went the extra mile.”

“It’s always 45MPa+ concrete with an 8% addition of silica fume (microsilica), which has a bit of a reputation for being sticky and hard to use, while being exceptionally durable,” adds Tim. “We managed to make two special mixes for the main contractor which could be pumped and had to get through some tight spaces full of reinforcing steel! The Firth team in Rotorua are no strangers to the less aggressive XA2 environment for surrounding areas, but due to the location of this project we went the extra mile.”

Concrete and more concrete ...

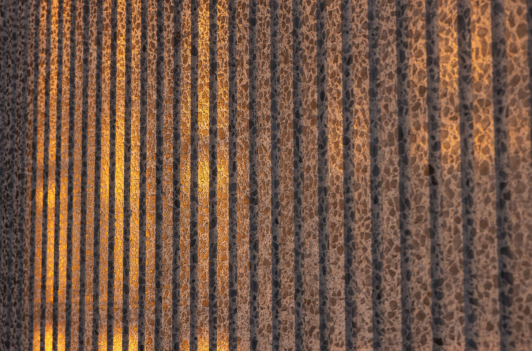

“Concrete has been used in many parts of the building in different ways and finishes,” adds Alex. “Decoratively, there are six types of precast panel finishes: Black Oxide - off the board formed concrete; Black Oxide - Honed and polished; Natural Honed and Polished; Steel shuttered concrete; Monarc machine-cut ribbed concrete and Exposed Aggregate concrete.”

“The Wai Ariki patterned panels were specified as an F6 finish, and the rest of the finishes were F5 where exposed. Of particular importance were the Monarc ribbed panels which we worked on very closely with Hawkins (the main contractor) and Nauhria (the pre-caster) to achieve the finish we wanted. The columns holding up the roof were also of great importance architecturally and specific steel moulds were developed to achieve an F5 finish. We wanted the building to achieve a handcrafted texture and hence concrete was selected for its natural aesthetics and imperfect finish.”

And then there’s the outside …

And then there’s the outside …

The entrance to Wai Ariki is guarded by six statues of tīpuna (ancestors) of Ngāti Whakaue (see main image) which are surrounded by paved areas and landscaping designed by Matt Peacocke, Landscape Architect and Principal at Boffa Miskell.

“Our involvement in the design of Wai Ariki began at concept stage, and continued through all stages,” says Matt. “The paving response has been designed to provide a sense of quality along the streetscape, whilst providing opportunities to reflect local colours, textures and narratives, tying the building into the landscape. Ultimately, we went with a simple speckled layout response to settle the building into its surroundings, and not take away from the complexity and boldness of the architecture. Durable Firth Piazza 50mm (honed) were selected due to their cost-effectiveness and availability for such a large area of paving, and we selected natural colours (Piazza® 50mm in Glacier Municipal and Volcanic Ash Municipal) which were honed to suit the local context.”

Wai Ariki is a stunning piece of architecture and a credit to all those involved from concept through to completion. Uniquely built on the legacy of Ngāti Whakaue culture, healing practices and manaakitanga – the centuries-old and internationally renowned Ngāti Whakaue concept of welcoming manuhiri (visitors) - Wai Ariki is open to all who wish to experience this unique cultural experience.